Earth Drill

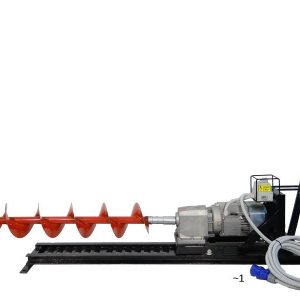

Horizontal earth drilling equipments are the best, cost-effective solution drilling under roads or any other surface block without breaking them. It is the most efficient way to place into the ground the electrical cables, the water, gas and sewage pipelines or any other required infrastructural facilities should run under the ground. The maximum drilling range is 15 m and they can be used in most type of grounds. Each drill-bit is 1 m long and they can be connected by their ends one by one as the drilling proceeds. The drill-bits can be ordered with diameters of 130, 200, 250 mm.

Some feature benefits of our drilling machine:

Easy setting up and operation

Fast and efficient working

Simple but massive construction

High quality, standardized electric components (electric version)

original HONDA engine (petrol version)

Strong mechanical parts and frame

Types of earth drills:

HONDA engine horizontal earth drill

Electric horizontal earth drill

We us only the best quality parts to build the HONDA engine equipments. The HONDA engine, the massive gearbox, the durable belt are the key elements of the drilling unit.

Engine data:

Honda GCV160 OHC

4,0 kW / 5,5 LE

Weight: 61 kg

unleaded petrol 95

The one-phase or three-phase electrical unit can work anywhere using the standard electric networks, power consumption: 12 A, 230 or 400V/50Hz. If supplied from generator it should be at least 3,5 kW output, 12A.

The generator must be placed far enough from the starting pit to avoid the exhaust gas filling the working area.elektromos_motor.jpeg

Engine data:

1,5 kW electric engine with gearbox

Weight: 46,5 kg

230 or 400 V/50Hz, 210Nm, 40 RPM

sin.jpg

Guide rail: The drilling unit moves forward and backwards on it. Fixed to the ground with spikes, see below. Measures: Length: 1700 mm, Width: 400 mm, Height: 45 mm, Weight: 10,5 kg

Pushing rod: Assures the forward pushing. Length: 1500 mm, Width: 400 mm, Diameter: 42 mm, Weight: 4,2 kg

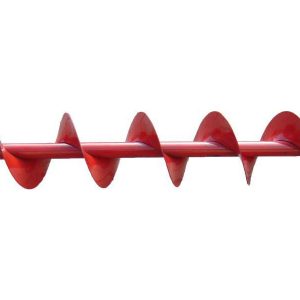

Drill-bits: Delivering the torque to the drill head and cleaning out the hole. Drill-bits can be fixed to each other in different orders (changeable). We provide 10 pieces of bits to each drill unit. Length: 1000 mm, Diameter: 130, 200, 250 mm. Weight: 130 mm – 7,5 kg, 200 mm – 8,5 kg, 250 mm – 9,5 kg.

Drill head: To cut out the earth and transfer it to the drill-bits. Drill head has a low reacting force, two-edges, „butterfly head” and can be connected to any of the drill-bits. The two-edges drill head helps to make the drilling precise and more efficient.

Length: 200-300 mm, Diameter: 130, 200, 250 mm. Weight: 130 mm – 3 kg, 200 mm – 3,5 kg, 250 mm – 4 kg.

Spikes: It is to put down through the guide rail into the ground in order to fix it and avoid the drill unit move away. Length: 35 mm, Diameter: 10 mm, Weight: 0,5 kg

Cardan-shaft: Aligning (if it is necessary) the chuck and the drill-bits during the drilling process. Weight: 3,5 kg.

Use of Method

Earth drill can be used under the ground horizontally

The drill head works in the ground and the engine assures its turning. The drilled earth will be removed out of the hole by the turning of the connected drill-bits. The soil will be taken out of the hole by a worker with a help of a shovel. Pushing forward the drill unit is done by forcing the pushing rod on the guide rail. Using additional drill-bits after each other the required length of the hole will be drilled.

Applications

The drill is very useful tool making the hole under the ground for electrical cables, water pipes and any kind of lines or networks. In this industry many times happened that these kind of works had to be done without breaking the surface or road. Without the right kind of tools huge additional costs, big problems can occur and delays in deadline.

Max. range of the earth drill is 15 m.

It can be used in different type of soils, either a loose sandy soil, a hard clay surface or pebble ground.

Showing all 11 results

-

AUGER Ø250MM×1M FOR EUROKOMAX EARTH DRILL MACHINES

169€ Add to cart -

AUGER Ø200MM×1M FOR EUROKOMAX EARTH DRILL MACHINES

158€ Add to cart -

AUGER Ø130MM×1M FOR EUROKOMAX EARTH DRILL MACHINES

146€ Add to cart -

DRILLING BIT Ø250MM FOR EUROKOMAX EARTH DRILL MACHINES

78€ Add to cart -

DRILLING BIT Ø200MM FOR EUROKOMAX EARTH DRILL MACHINES

76€ Add to cart -

DRILLING BIT Ø130MM FOR EUROKOMAX EARTH DRILL MACHINES

74€ Add to cart